Preventive Service Maintenance

All material handling equipment should undergo periodic preventive service maintenance to ensure efficiency and effectiveness. By immediately identifying problem areas and making minor necessary repairs, costly downtime to your business operations can be prevented.

Benefits of Routine Equipment Maintenance:

- Prolong your equipment’s life span

- Enhances the equipment safety features

- Maintain your equipment at its optimum working condition

- Reduce unanticipated breakdowns and maintain smooth production, thus reducing operation downtime

- Early detection of equipment abnormalities, follow-up repairs can be scheduled at your convenience

- Planning ahead for a conducive shutdown period

EMERGENCY RESPONSE & 24 HOUR SERVICE

INTERLIFT fully understands the importance of keeping your facilities running at all times. Downtime with your material handling equipment can be costly and may affect your company’s productivity and bottom line. For this reason, we have put in place a 24-hour service hotline to attend to your repair needs. Just call us when your material handling equipment is down and we will solve your problem promptly.

INTERLIFT is well equipped with a wide range of spare parts that enables us to respond swiftly to your equipment repairs and service requirements.

INTERLIFT STRIVES TO ACHIEVE ALL BREAKDOWN RESPONSE WITHIN 4 HOURS*

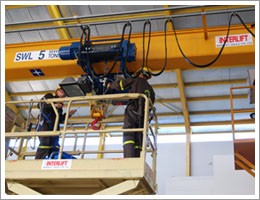

MOM STATUTORY VISUAL INSPECTION & LOAD TESTING

INTERLIFT can assist to ensure all your lifting equipment go through the mandatory MOM statutory yearly visual inspection and 4-yearly load test. The equipment will be tested vigorously and in compliance with our local SS497 standard.

MODIFICATION & UPGRADES

Upgrading or modernising existing equipment is a cost-effective solution for meeting your changing business needs and extending the lifespan of your equipment. Our specialised service teams will conduct a comprehensive analysis of your existing equipment, recommend and make the necessary improvements.

We can provide the following modifications:

- Amendment of the equipment SWL capacity

- Adjustment of the Crane Hook Path (Height of Lift)

- Installation of Overload Limiter or Close Space Limiter for your equipment

- Upgrading the conventional Cable Pendant Control to Wireless Radio Remote Frequency Control System

- Add Load Displays, Anti-Sway systems to your crane

- Provision of Human Sensor along the moving end carriage for your gantry cranes

- Upgrade your equipment to meet local up-to-date SS497 standard and MOM WSH Regulations

CRANE REFURBISHMENT

INTERLFT offers total crane refurbishment services

- Old and worn crane parts or components can be refurbished

- Motor rewinding services

- Changing of C Track and Flat Cables System

- Overhauling

- Painting of whole crane structure

- Replacement of SWL stickers

CRANE DISMANTLING & RELOCATION

INTERLIFT has an expert team of engineers who can dismantle and relocate any type of crane.

Our scope will include:

- Dismantle every part and component of any type of crane

- Provision of logistics facilities to transport them to a new site

- Reassemble them like they were before with refurbishment of worn or faulty parts/components

- Conduct MOM load testing and commissioning to ensure crane is in accordance with local SS497 standard